Static sealing

Encapsulated joints are usually composed of an elastomer core (Viton or Silicone)coated with FEP ® fluoropolymer sheath or Teflon PFA ®.

This concept combines excellent chemical resistance, good mechanical protectionand sufficient elasticity to achieve a reliable seal in the long term.

Advantages :

– Good compression ratio

– Extruded materials to guarantee dimensions (no air infiltration)

– 100% pure, high quality materials (DuPont ™ licensee)

– Excellent chemical resistance

– Wide dimensional range

– Possibility to make specific profiles and dimensions on request.

Vulcanized joints (Vulc O rings):

These joints are made by extrusion more welding, they have a high level of performance while maintaining great versatility compared to a molded joint solution.

Advantages :

– High quality

– All diameters achievable

– 100% pure, high quality materials (DuPont ™ licence)

– Very low tooling cost

These seals are available in many sizes and have 95% strength of a fully molded seal. They have a very low compression ratio because of the high quality of the materials used (DuPont ™ licence). The seals are designed with tight tolerances (E1; ISO3601-3 ‘Grade CS’); ± 0.5mm

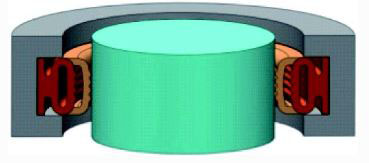

Inflatable seals

Inflatable seals are recommended for high level sealing applications (nuclear, chemical industry …).

Their expansion makes it possible to compensate for a contours and to apply pressure constant over the entire outline of the joint.